How structural details shape safety, reliability, and performance

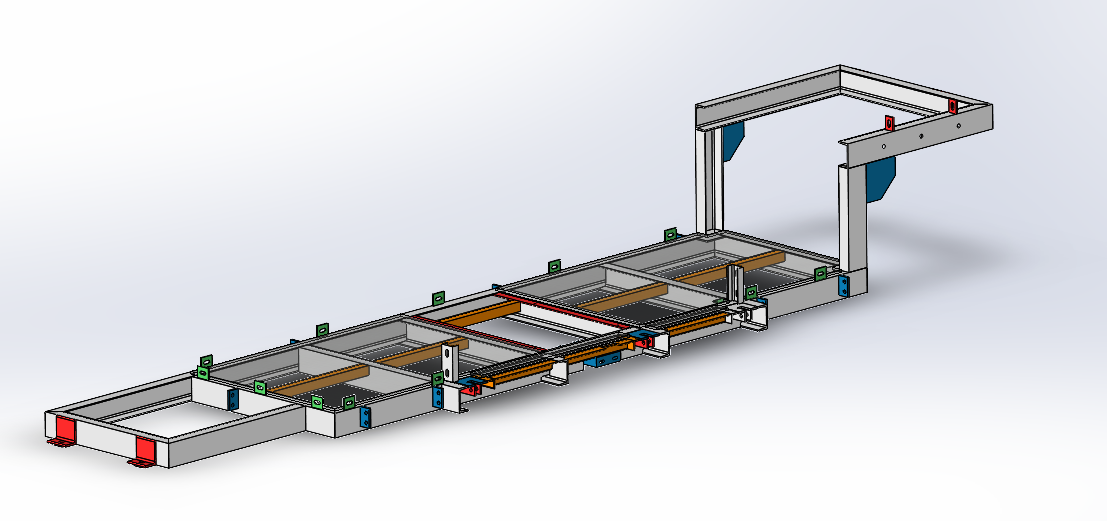

In the world of port operations, where time is money and safety is paramount, the design of modern port cranes—such as RTG, PT, RMG and QC cranes—relies heavily on high-quality steel components. While the spotlight often shines on the cranes’ lifting capacity or automation systems, the structural accessories behind their stability and usability deserve equal attention.

The Hidden Backbone of Port Cranes

Steel components such as working platforms, handrails, and custom accessories are vital to the crane’s overall functionality. These elements:

-

Ensure safe access for operators and maintenance teams

-

Provide rigid, vibration-resistant surfaces at height

-

Allow proper positioning of control equipment and safety systems

-

Support the modular assembly of large crane structures

At Vietwalk, we specialize in supplying these crucial elements—custom-designed, precisely fabricated, and built to endure.

Designed to Fit, Built to Last

Each port crane has its own blueprint. That’s why off-the-shelf components rarely deliver the performance or safety needed in harsh port environments. Instead, custom-fabricated steel structures ensure:

-

Dimensional accuracy for seamless integration with the mainframe

-

Material strength to withstand load stress, wind, and corrosion

-

Compliance with international safety standards

-

Flexible installation, whether bolted or welded

We work directly from customer drawings and technical specs, delivering components tailored to your system—down to the millimeter.

Types of Structural Components We Deliver

At Vietwalk, our product portfolio covers:

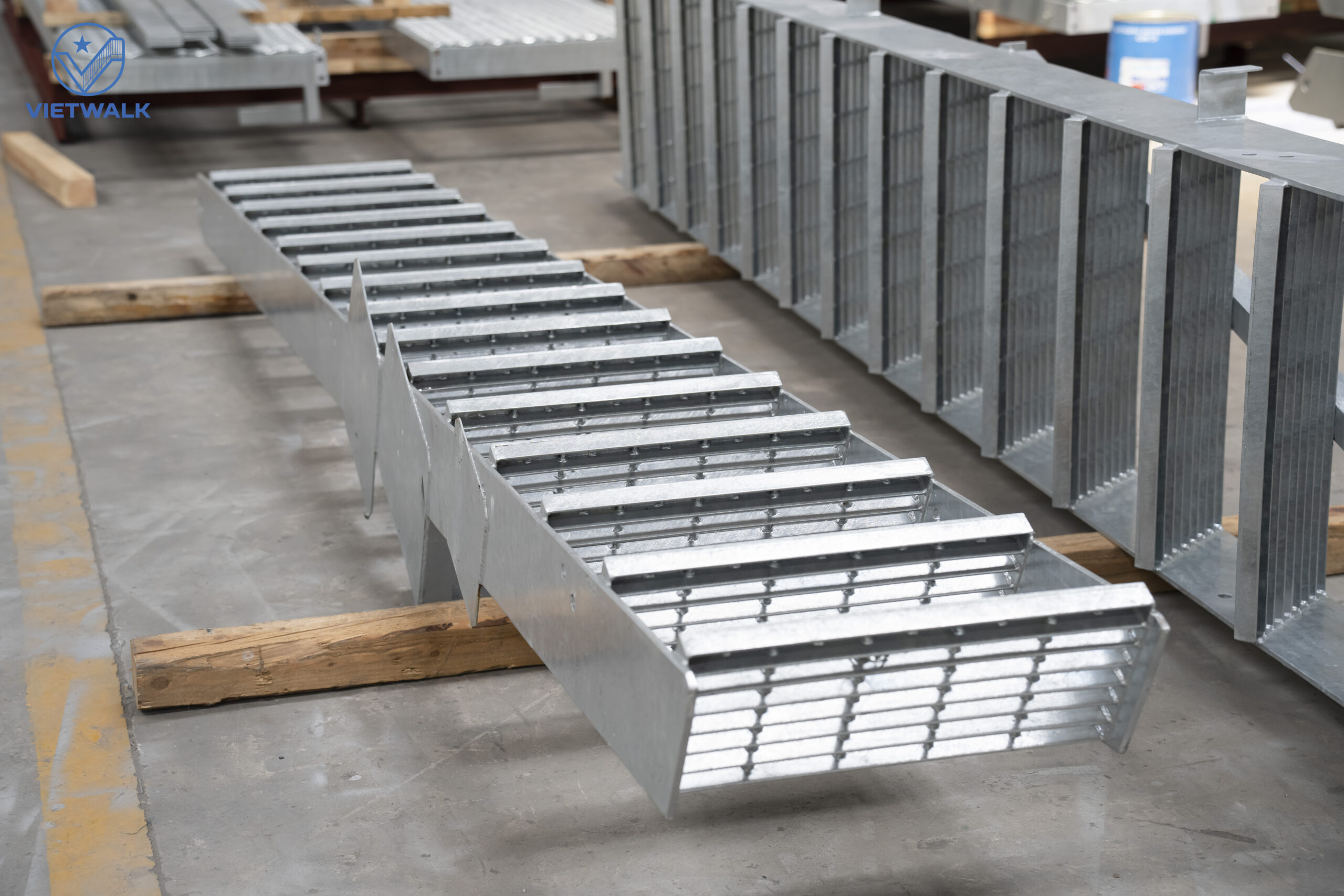

Platforms: anti-slip surfaces for safe access to crane modules

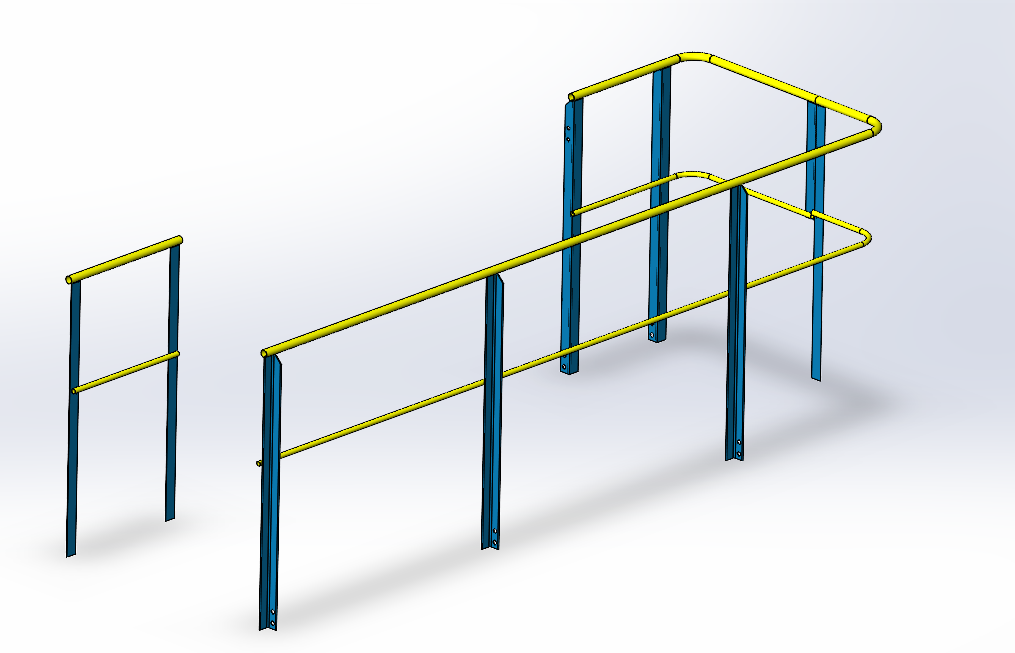

Handrails: corrosion-resistant and compliant with EN/OSHA safety codes

Stairways and ladders: secure access solutions for multi-level structures

-

Accessories: base plates, brackets, ladders, toe plates, and more

-

Custom parts: anything your engineers design—we can build it

These aren’t just add-ons. They’re mission-critical for long-term crane performance and operator safety.

Built for Harsh Conditions

Operating in coastal and maritime environments means constant exposure to salt, moisture, and temperature changes. That’s why we offer:

-

Hot-dip galvanizing

-

High-durability coatings

-

Welding inspections and certifications

Our products are engineered not just to perform, but to last.

Trusted by Global OEMs

Vietwalk has a proven track record supporting leading crane manufacturers. With decades of fabrication experience and long-term partnerships, we’ve supplied components for large-scale crane projects across Asia and beyond.

Ready to Strengthen Your Next Project?

Looking for reliable structural components for your crane system? Let’s talk.

Contact Vietwalk today to learn how our steel solutions can power your next project.